Clean lines in a natural wood veneer wall aren’t an accident. They come from a layout that’s been thought through, panel sizes, seams, corners, and transitions, so the finish reads as intentional from every angle.

Jacaranda’s Architectural Panels and Reveals are built for those projects where the details matter as much as the veneer itself. Architectural Panels deliver a consistent finish on a stable substrate, while reveal systems help keep spacing true and create precise joints that hold up in real-world construction.

Start with a seam plan that stays straight

“Crisp” is really about control: controlling where seams land, how corners terminate, and how adjacent materials meet. Before anyone installs veneer, lock the grid and the transitions.

- Pick a module size that works with the room geometry and the wall conditions.

- Decide which lines are “hero lines” and keep them continuous across walls, soffits, and returns where possible.

- Coordinate edge conditions early, square, profiled, or bullnose, so corners and reveals don’t get improvised in the field.

Architectural Panels for consistent finish and fast turnaround

When you need repeatable quality across a wall system, Jacaranda-fabricated SanFoot Architectural Panels are designed to provide a consistent finish with a faster path from spec to install. Panels can be supplied on multiple substrates, including plywood, MDF, and other fire-rated or non-combustible options with edge finishes that match the design intent.

- Substrate flexibility: plywood, MDF, and other rated substrates depending on the project needs.

- Edge options: square, profiled, and bullnose configurations for clean terminations.

- System thinking: panels can integrate with adjacent SanFoot wallcoverings and architectural millwork as part of a turnkey wood solution.

Reveals that turn joints into a design feature

Reveals that turn joints into a design feature

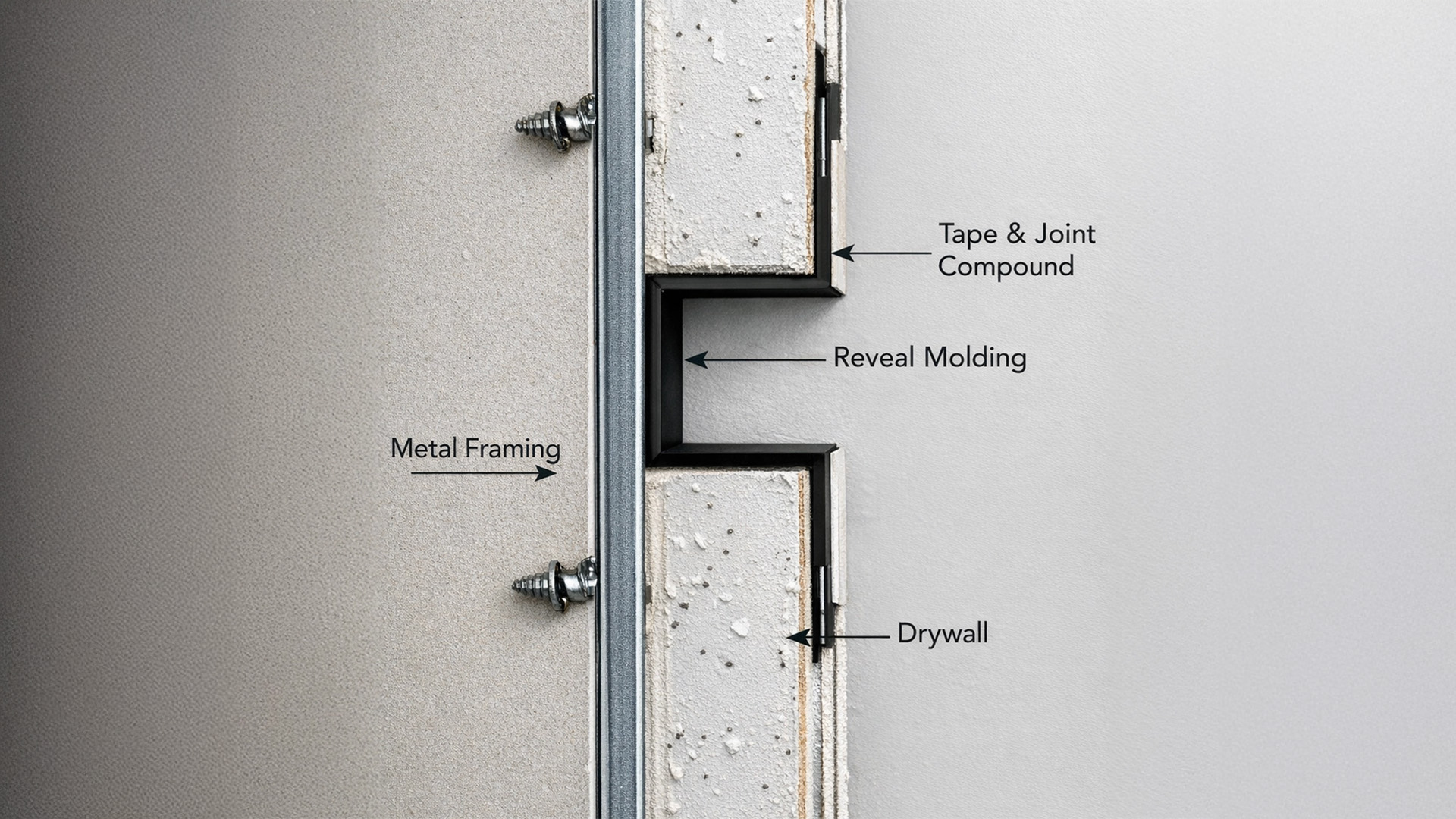

Reveal systems help you get the spacing and alignment you drew, then keep it true after installation. Aluminum mouldings and reveals are a versatile approach for drywall panel systems, allowing SanFoot wallcovering to be applied directly to a drywall finish.

- Transitions between planes and dissimilar materials for cleaner, more durable junctions.

- Finish options: standard anodized and powder-coated finishes to coordinate with adjacent materials.

- Recycled content: extruded aluminum with a minimum of 65% post-consumer recycled content.

- Design range: reveal widths from 1/8 inch to 6 inches depending on the visual effect you want.

- Common profiles include rectangular reveals, “V” reveals, wall/ceiling abutments, reveal base mouldings, and corner mouldings.

Planning Checklist for Panels and Reveals

Planning Checklist for Panels and Reveals

Clean natural wood veneer walls come down to decisions made early, before shop drawings lock in, and definitely before anyone is installing in the field. When panels and reveals are part of the design, these are the details we like to confirm up front so the finished wall reads exactly as intended.

- Set the grid first: confirm panel sizing and reveal placement so seams land intentionally.

- Choose substrates with purpose: align substrate selection with performance requirements and install conditions.

- Confirm edge conditions: decide on square, profiled, or bullnose edges so corners and terminations stay clean.

- Plan transitions early: identify where the veneer meets other materials, millwork, ceilings, bases, and adjacent finishes, and detail those junctions before fabrication begins.

- Coordinate lighting and sightlines: reveals and seams read differently under grazing light; confirm where shadow lines will be celebrated and where they should disappear.

- Mock up the critical corner: if the project includes a feature wall, long corridor run, or high-visibility lobby surface, a small mockup helps confirm reveal width, finish read, and alignment.

For projects that rely on precise alignment and intentional joints, start with Architectural Panels & Reveals and use Jacaranda as a technical resource during layout and detailing to keep the installation consistent from first panel to final reveal.